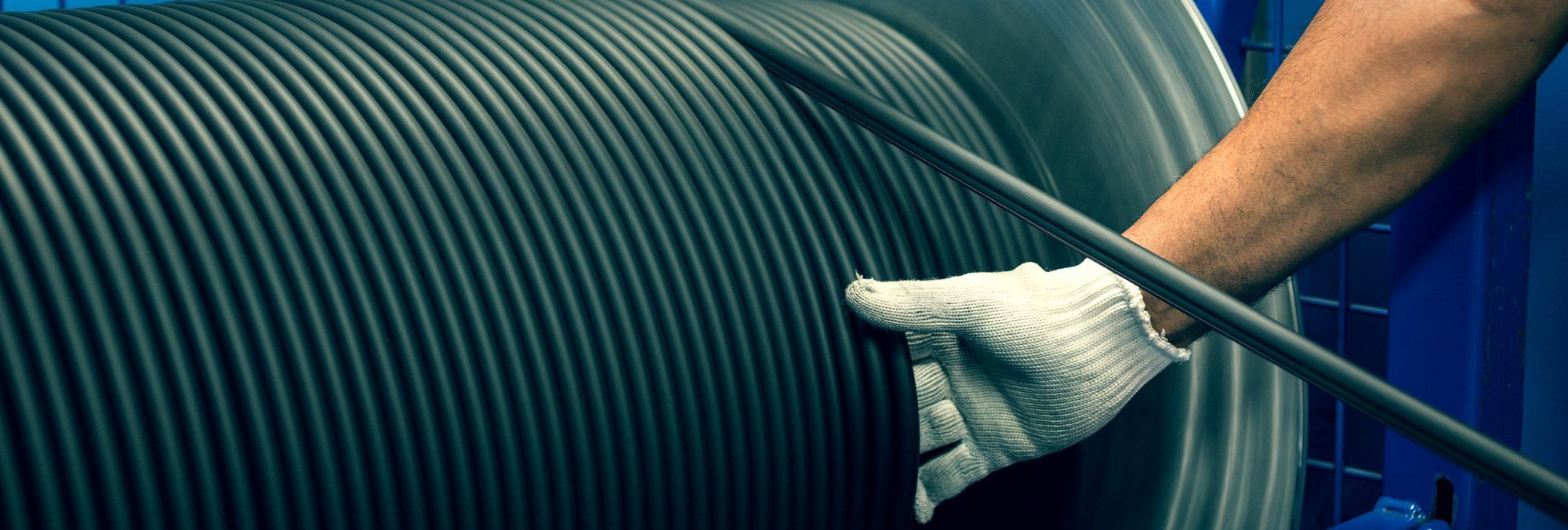

Extrusion

In the extrusion elastomers are processed continuously under high pressure through an extrusion die. This process creates a profile according to the shape of the cross-sectional geometry. As the profile is continuously produced its length can be infinite. Through our long experience and know-how, we are able to produce almost any geometry and material combination. From simple one-component products to highly complex five-component sealing profiles. With TPE profiles you are able to gain a higher flexibility in the structural sealing design. TPE extrusion offers advantages in recycling and weight reduction. The traditional classic version to produce sealing profiles is the EPDM extrusion. SaarGummi manufactures profiles in various combinations of materials, also available with slip-coating and/or flock application. Hybrid profiles combine the advantages of EPDM and TPE material properties. As an example this technology is used for TPE slip-coatings on EPDM glass run channel profiles. This technology makes usage of conventional slip-coating and/or flock obsolete.